Power System Engineering

Optimize the Design, Function, and Operation of Your Protection System

Ensure minimum service disruption with proper system coordination

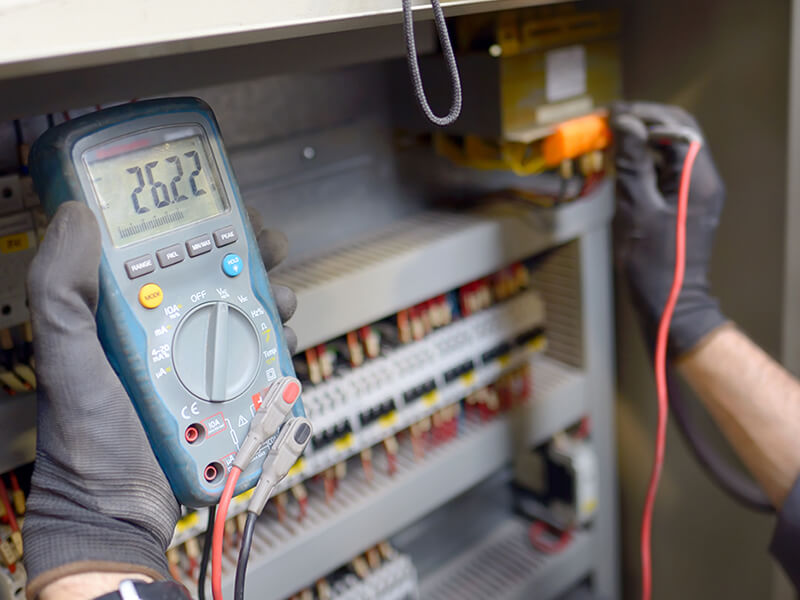

A short circuit and coordination study helps to avoid accidents, productivity losses, costly fines, and higher insurance costs. By evaluating a system’s protective devices and the circuits they protect, a coordination study determines how long equipment can sustain operation without damage or failure. These studies provide power transformers, switchgear, substations, motor control centers, panelboards, and other equipment with the required protection to ensure minimum service interruption under overload and short-circuit conditions.

Learn MoreMitigate your risk and ensure compliance with Vertiv’s arc flash analysis

Electrical hazards such as electrical shock and arc flash impact workers every day in the United States. An arc flash analysis can help determine the presence and location of potential hazards and provide recommendations for Personal Protective Equipment (PPE) and flash protection and safe work practices. National Fire Protection Association (NFPA) requires this analysis be performed at least every five years or as modifications or expansions to your electrical distribution system are made, or as changes occur in the electric utility system. Vertiv’s team of registered professional engineers review and stamp each arc flash analysis ensuring accuracy and compliance.

Learn MoreDetect, identify and address costly power quality issues

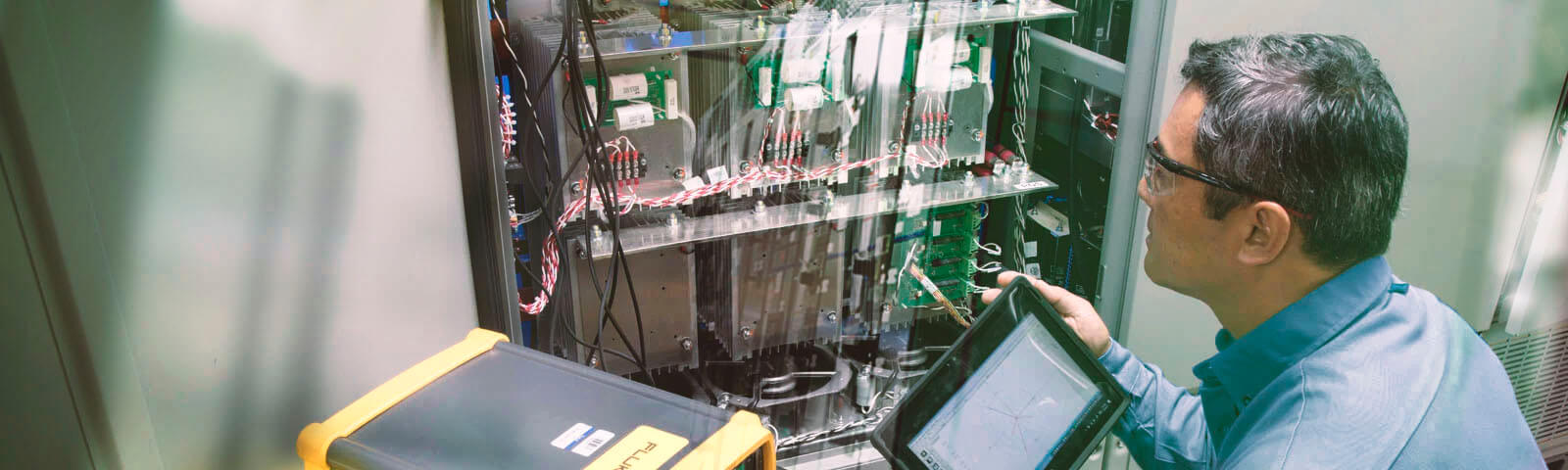

Today’s increasing sensitivity of advanced process controls and industrial machinery as well as sophisticated IT equipment require a higher level of power quality to ensure smooth operation and extended service-life of the equipment. Vertiv engineers help identify the source of the disturbances such as grounding errors and harmonic distortions and recommend solutions to ensure optimal system performance.

Learn MoreEnsure your electrical system is sized and configured for maximum capacity

Load flow studies help identify and correct power system issues, such as overloads, load imbalance, harmonic problems, poor power factor, or other factors that may be causing operational inefficiencies or performance problems. Our power system engineers will evaluate component and circuit loading, power factor and system losses and real and reactive power flow and provide recommendations to help you fine-tune your electrical system for optimal efficiency and capacity.

Learn MoreProtect your people, equipment and business with proper grounding

A grounding system is one of the most important, yet neglected, segments of a critical facility’s electrical power system. Proper grounding is essential to ensure personnel safety and service reliability. Vertiv’s Electrical Reliability Services can provide a study on a proposed substation ground grid design to ensure safer and more cost-effective ground grids.

Learn MoreConfigure your relays for maximum system protection while fully adhering to applicable NERC requirements

Vertiv’s protection and control engineers can help determine the best configurable relay settings and logic to provide maximum system protection, advanced functionality, and compliance with NERC requirements. Our engineers will take time to fully understand and define your system's requirements, such as how the protection system should respond in the event of a fault, how protective relays should communicate with other systems, and what functions, in addition to protection, the relays should perform.

Learn MoreEnsure accurate and up-to-date engineering drawings and documentation

Vertiv engineers can help modify existing CAD drawings or create new drawings such as one-line diagrams, control schematics, wiring drawings, panel elevations and more. We have the applied installation experience and a quality process to ensure the creation of accurate and precise diagrams and schematics of your existing or newly updated system.

Learn MoreWe would love to work with you to solve your electrical reliability challenges! We will respond quickly to your inquiry.

Please feel free to contact us:

By Web: Online Form

By Phone: 1888.468.6384

- Deep infrastructure expertise across entire electrical system, from generation and transmission to distribution infrastructure

- 45 years of experience in electrical testing, maintenance and engineering, and proudly serving over 15,000 valued customers

- Active participant in numerous national organizations to create and lead standards development, including NFPA, IEEE, and NETA

- Industry leader in staffing Level III and IV NETA-Certified technicians

- Superior safety ratings, safe work practices, and award-winning safety programs

- Lowest employee turnover rates in industry

- Industry-leading customer satisfaction and Net Promoter Score

- LEED Gold-Certified state-of-the-art learning center with 11,000 square foot equipment lab in Westerville, Ohio, and 3 regional training facilities

- Courses approved by OSHA, MSHA, IBEW, U.S. Department of Energy, U.S. Department of Defense

Power System Engineering Studies

Short Circuit and Coordination Studies

Arc Flash Studies

- Arc Flash Solutions

- OSHA 1910/NFPA 70E Training

- NFPA 70E 2018 changes Safety Bulletin

- NFPA 70E 2018 Fact Sheet

- OSHA Publishes First-Ever Arc Flash Protection Requirements for Electric Power Industry

- Electrical Reliability Services Overview

Power Quality Studies and Harmonic Analyses

Load Flow and Power Factor Studies

Grounding Studies

- Why Test? Grounding Systems

- Why Test? Ground Fault Protection Testing

- Why Test? Protective Ground Sets

- Why Test? Why Mines Test Grounding Systems

System Logic and Control Settings

- Configuring Microprocessor-Based Relay Systems for Maximum Value

- Case Study : Tri-State Generation & Transmission

Engineering Drawings