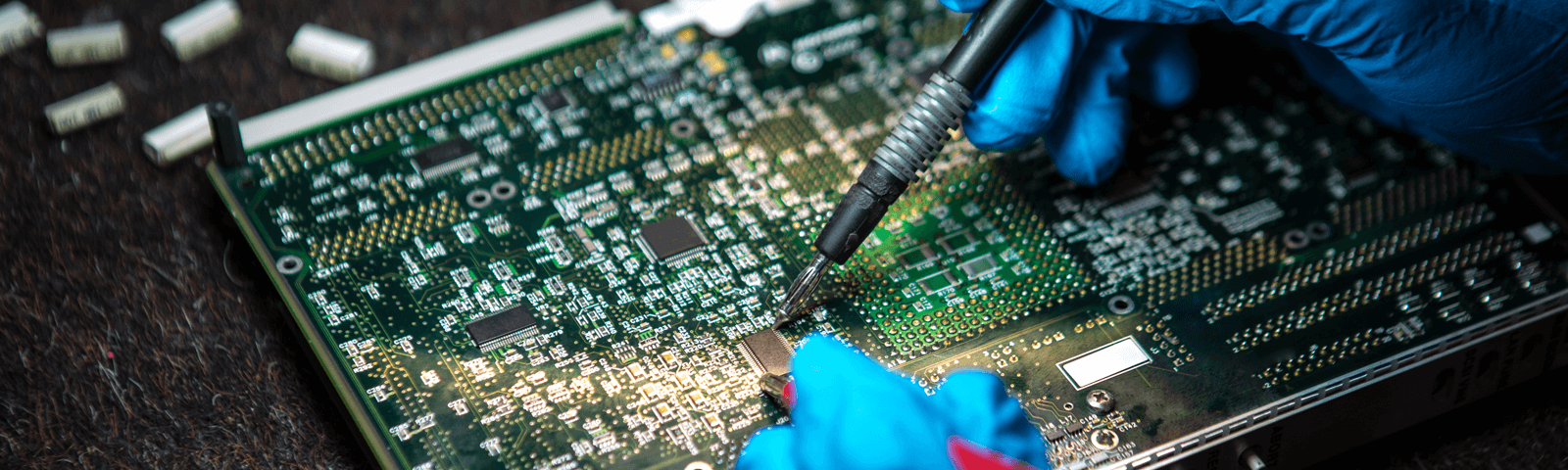

In an age where everything is becoming increasingly computerized and the thought of manufacturing 4.0 is more than just a buzzword in the industry, the semiconductor companies needs to keep pace with the ever-evolving market and emerging technologies by future-proofing their processes. Here at Vertiv, we offer unique solutions that support sustainability, flexibility and efficiency fit for the requirements of the semiconductor manufacturing process. With proven industry expertise backed by global service support, our solutions are aimed at protecting high-value assets in your facility, ensuring production continuity to help you meet service-level agreements and deliver the best quality products to your customers.

READ BROCHURE

Digital Trends Shaping the Semiconductor Industry

How is technology disrupting the semiconductor market? Below are three trends that are seen to impact the industry.

Digitized product and service offerings

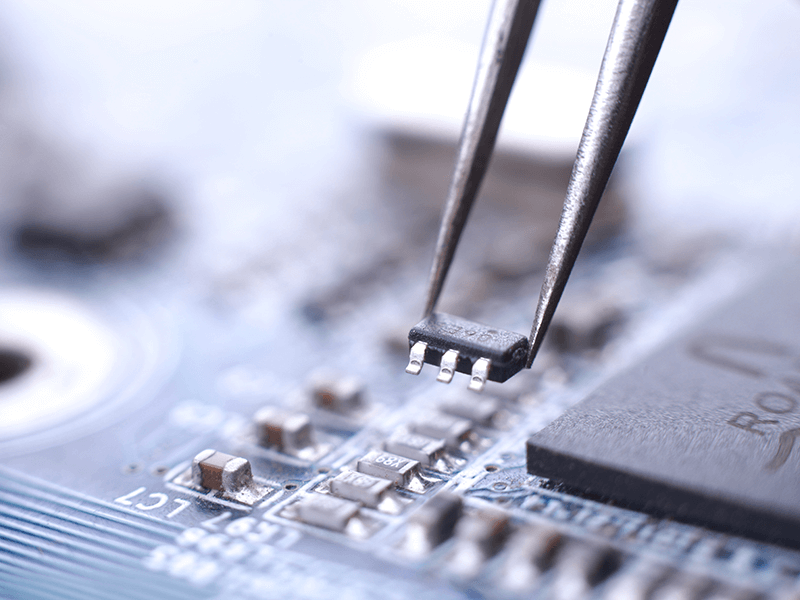

- Harnessing technology to develop innovative chips will be essential in addressing today’s rapidly evolving market.

- From AI-integrated chips to increased customization, these innovations will bring more added value to existing products by chipmakers.

Digital value chain

- Several business models that leverage on technology and added intelligence are available for semiconductor makers to explore to enhance their capabilities and adapt to customer expectations.

Digital business models

- Leveraging on AI-driven capabilities to boost end-to-end value chain will be crucial in enhancing efficiency within the manufacturing area.

Infrastructure Challenges

- Growing customer demands and expectations are putting pressure on manufacturers to make sure they meet or even exceed production schedules.

- Protection of manufacturing equipment is critical, as downtime means lost productivity, penalties, damaged reputation and lost revenues.

- There are many causes of downtime, but many equipment-related failures can be preventable.

- Therefore, it is important to maintain reliability through regular facility testing and by utilizing solutions that protect against common causes of breakdowns such as power surges and electrical spikes.

- With increased reliance on automation and artificial intelligence, manufacturers must be able to come up with ways to seamlessly integrate technology into everyday manufacturing operations.

- AI and robotics are increasingly being used on the manufacturing floor to speed up manufacturing processes.

- Manufacturing equipment should be optimized and designed to accommodate technology integration through the use of predictive tools as well as power availability.

- Digitization and automation are increasingly being adopted by manufacturers to improve efficiency and overall operations.

- Manufacturers must be able to come up with ways to seamlessly integrate technology into everyday manufacturing operations.

- Equipment should be optimized and designed to accommodate technology integration through the use of predictive tools as well as power availability.

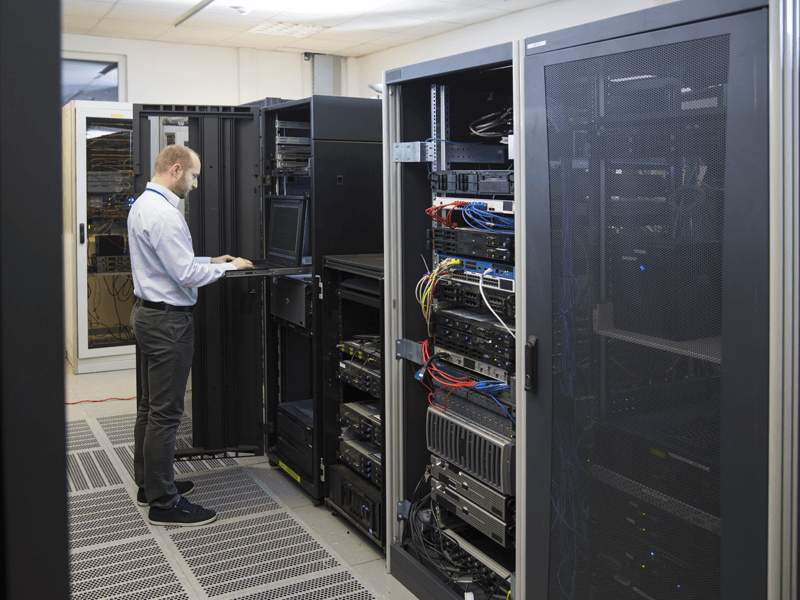

- IT infrastructure becomes all the more critical in the age of automation and IoT, and IT managers must have the right infrastructure in place not only to support the uptick in compute requirements, but also to manage the entire manufacturing facility better and smarter.

- The use of Artificial Intelligence (AI), Machine Learning (ML) & Robotics in manufacturing means an uptick in computing power and demand. Necessary solutions that are rugged and efficient are critical to support corporate demands in a manufacturing environment.

- As they strive to create a leaner, more efficient supply chain systems, manufacturers need to be aware of key supply and demand information in real time, right up to the shop floor – to be able to adjust production SKUs and schedules.

- A facility or IT manager will need to be able to see a problem before it becomes a problem – and be able to do something about it.

- Predictive monitoring tools can aid in having a smarter supply chain network. These tools must be able to predict, diagnose and provide action on all areas of the manufacturing network (from the environment, equipment or IT network) to ensure process continuity at all times.

Vertiv Protects Critical Processes in the Semicon Space

Reshaping the manufacturing operations to improve efficiency and flexibility

| Design and Material Retrieval | Central Control Room |

| Front-End Production | Information Technology |

| Back-End Production |

Featured Vertiv Solutions

We provide a full range of solutions designed to fulfill the unique requirements of Semiconductor Industry

Liebert ITA2

Compact, Efficient, & Robust UPS for Critical Applications

Liebert Hipulse-U

Utmost Reliable Power Solution for Critical Business Applications

SmartCabinet™

Intelligent, Integrated Containment for IT Infrastructure

Liebert® DM

High Performance Cooling for Small Technological Rooms